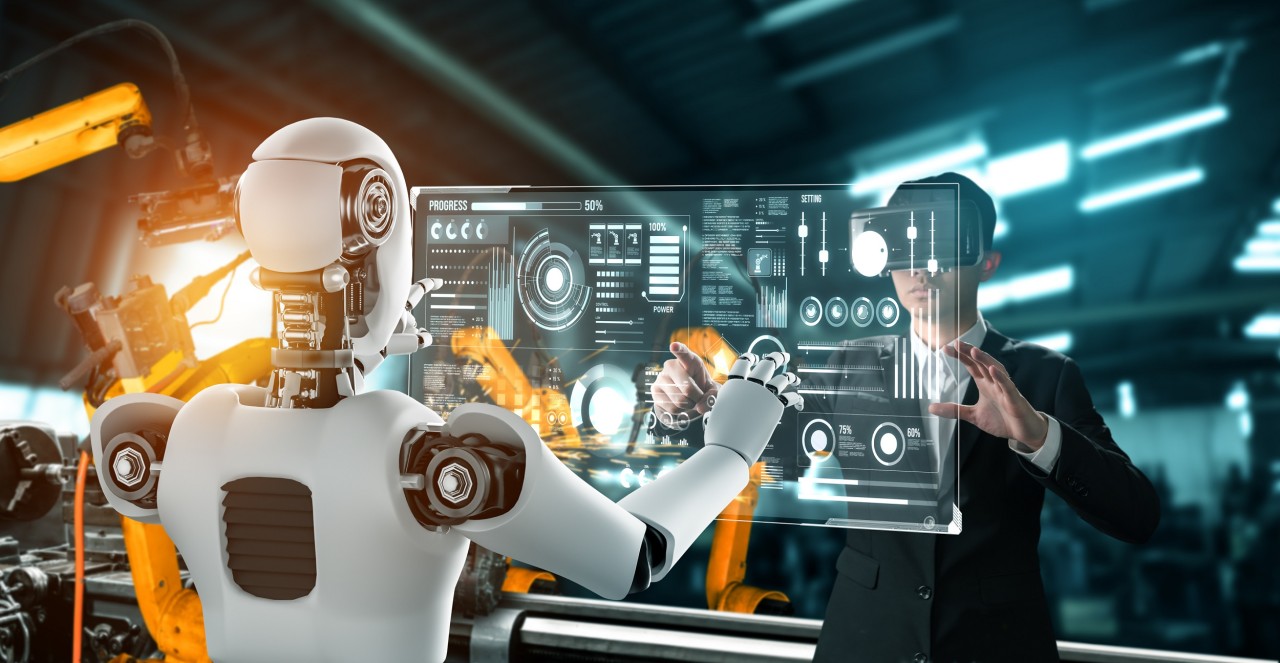

Welcome to a journey into the future of industrial automation, where robotics and artificial intelligence (AI) are not just buzzwords but the backbone of modern manufacturing and production processes. The evolution of these technologies is rapidly reshaping industries, making operations more efficient, cost-effective, and innovative. Let’s dive into how robotics and AI are spearheading this transformative era and what the future holds for industrial automation.

The Rise of Robotics in Industry

Remember the days when robotics in the industry was a concept straight out of sci-fi movies? Well, those days are long gone. Today, robots are an integral part of the manufacturing floor, performing tasks ranging from assembly to packaging with precision and speed unmatched by human hands. But it’s not just about doing things faster; it’s about revolutionizing how tasks are approached, with minimal error rates and higher quality output. Robotics technology continues to evolve, becoming more adaptable and intelligent, capable of taking on complex tasks and working side by side with human counterparts.

As robots become more sophisticated, they’re equipped with sensors and AI algorithms that allow them to learn from their environment and improve their performance over time. This adaptability is key in environments where customization and flexibility are paramount. The integration of robotics in industry signifies a shift towards a more dynamic, responsive manufacturing process that can quickly adjust to market demands and changes.

Artificial Intelligence: The Brain Behind the Brawn

While robots may be the hands of the operation, AI is undoubtedly the brain. AI’s role in industrial automation cannot be overstated, as it provides the intelligence that enables robots to perform tasks autonomously. From predictive maintenance and quality control to supply chain optimization, AI algorithms analyze vast amounts of data to make informed decisions, identify patterns, and predict outcomes with remarkable accuracy.

The real magic happens when AI is combined with machine learning and data analytics. This synergy allows systems to not only react to their environment but also learn from it, continuously improving their efficiency and effectiveness. AI’s ability to process and analyze data in real-time enables industries to become more proactive, predicting potential issues before they arise and optimizing processes for peak performance.

The Human-Robot Collaboration

One of the most exciting developments in industrial automation is the emergence of collaborative robots, or cobots. These machines are designed to work alongside humans, complementing their abilities and compensating for human limitations. Cobots are equipped with safety features and intuitive interfaces, making them accessible to workers without specialized training.

This human-robot collaboration enhances productivity and creativity, allowing human workers to focus on complex problem-solving and strategic tasks while robots handle the repetitive, physically demanding work. The result is a more agile, flexible workforce that can quickly adapt to new challenges and innovations.

Advancements in Sensor Technology

Sensors play a pivotal role in the integration of robotics and AI in industrial automation. These devices collect critical data about the operational environment, enabling robots to “see,” “hear,” and “feel” their surroundings. The advancements in sensor technology, including vision systems, tactile sensors, and environmental sensors, have significantly increased robots’ capabilities, allowing for more nuanced and sophisticated interactions with their environment.

With better sensors, robots can perform tasks with greater accuracy and adapt to changes in their environment more effectively. This is particularly important in industries where precision is crucial, such as electronics manufacturing or pharmaceuticals.

The Role of IoT and Connectivity

The Internet of Things (IoT) has transformed industrial automation by enabling devices and machines to communicate with each other and with centralized control systems. This connectivity allows for real-time monitoring and control of industrial processes, leading to significant improvements in efficiency, productivity, and reliability.

IoT devices collect and transmit data that AI systems can analyze to optimize operations, predict maintenance needs, and even adapt production processes in response to changes in demand or supply chain disruptions. The interconnectedness of devices and systems creates a more integrated, responsive, and intelligent industrial environment.

Navigating the Challenges

Despite the numerous benefits, the transition to a more automated industry is not without its challenges. Concerns about job displacement, cybersecurity threats, and the need for significant investment in new technologies are prevalent. However, by focusing on upskilling workers, implementing robust security measures, and adopting a phased approach to technology investment, industries can navigate these challenges effectively.

The Future of Work in an Automated World

The future of work in an increasingly automated world is a hot topic. While automation may change the nature of some jobs, it also creates opportunities for new roles that require advanced skills and creativity. The emphasis will likely shift towards jobs that involve managing and working alongside AI and robotics, data analysis, and strategic decision-making.

Ethical Considerations and Sustainability

As we embrace the future of industrial automation, it’s crucial to consider the ethical implications and the impact on sustainability. The adoption of robotics and AI offers the potential for more sustainable manufacturing processes through optimized resource use and reduced waste. However, it’s essential to ensure that these technologies are developed and used in a way that benefits society as a whole, without exacerbating inequality or harming the environment.

Looking Ahead: A New Era of Innovation

The future of industrial automation is bright, with robotics and AI paving the way for unprecedented levels of efficiency, flexibility, and innovation. As these technologies continue to evolve, they will undoubtedly unlock new possibilities and challenges, shaping the future of industries in ways we can only begin to imagine.

In conclusion, the integration of robotics and AI into industrial automation marks a significant leap forward in our quest for efficiency, productivity, and innovation. As we stand on the brink of this new era, it’s clear that the possibilities are as limitless as our capacity to imagine and innovate. The future is here, and it’s automated.

Explore the rest of our website Tech Glints, intriguing articles await you! Interested in contributing? Simply click the contact button at the top right. Thank you!